IAQ (Indoor Air Quality) Irritants

Volatile Organic Compounds

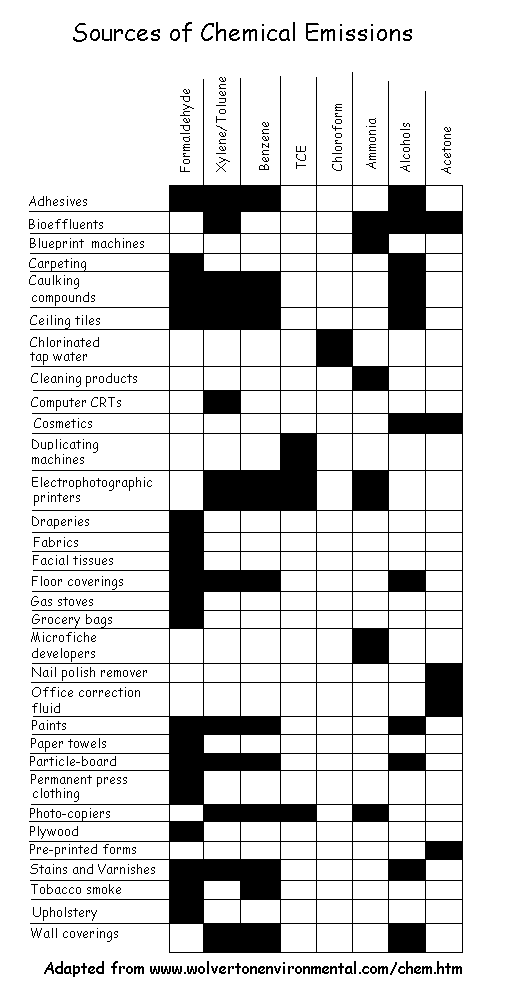

Non-microbial VOCs

VOCs are aromatic or out-gas byproducts (dry-out evaporation) of many chemicals in our "modern" environment. Paint for instance, is a liquid that is applied to surfaces for a certain color rendition. The emulsion within the paint fluid coats the surface it is applied to, while the liquid evaporates. The liquid is a mixture of many volatile compounds that can be biological irritants. Their dry-out can take as much as several weeks, but can be accelerated by a bake-out.

Engineered woods, plywood and particleboard in particular, are made of wood sheets or pieces that are glued together. The glues use a formaldehyde base that evaporates and irritates lungs, throat, and other organs. A couple contacted me about a smell they were perceiving from their polyurethane-treated hardwood floor. It had been treated two years prior, and they\\'d lived in the home since then. However, the summer just before, they\\'d left for a few weeks, and forgot to leave the air conditioning on. The structure experienced high temperatures, and the polyurethane treatment finally outgassed, saturating every porous material in the structure. - - - On a visit to a client\\'s residence, and upon descending into the basement, I perceived an oily smell, and asked where the oil furnace was. He advised it was removed more than a decade prior. However, due to many structures in the basement being porous, the smell of oil had remained long after the source was removed.

Plastics are usually produced with phthalates (plasticizers) to give them "that soft feel." Ever smell that "new car smell?" It is in part due to the phthalates evaporating, which also coat the inside of the windshield and cause a slightly opaque coating, not to mention the same addition to your lungs. Plasticizers can be as much as 50% of the material content of plastics. These evaporate and become biological irritants (try at home: place water in a polyethylene bottle and keep in storage for a few days, or even leave a water bottle in the sun for a couple of hours, then taste the water and its associated "plastic" flavor (Some plastic glasses can impart that plastic flavor in a matter of minutes!)). Plastics are encountered in furniture, kitchen utensils, office supplies, carpeting, clothing, and just about everything that can be manufactured. To add insult to injury, many carpets are treated with fungicides / pesticides, which volatilize into the indoor environment. In a new home, the out-gassing becomes a default contaminant of the breathable environment for many years, And if the owners immediately occupy the structure upon completion, they risk long-term effects that last well beyond the brief break-in or getting-to-know-you time in a new residence.

An engineered source of VOC pollutants is the hot water boiler. As it heats the water, the elevated temperatures make any VOC in the water more volatile. When the water is sprayed in the process of washing dishes, clothes, or showering / bathing, the VOCs become airborne. Water acquires these VOCs from ground contamination and runoffs, as well as water treatment processes. Chlorine and Fluorine, common water treatment chemicals, also become airborne, and irritate. While many domestic water supplies are reasonably clean, even trace amounts of certain VOCs are sufficient to introduce biological influence. While public water systems are regularly treated (chemically or by filtration), private ones are well worth sampling on a regular basis, yearly or more often, depending on test findings. If certain unwanted water contaminants are identified, then filtration or sterilization can be introduced.

In a public water supply system, Chlorine is a major concern. While doing its duty in killing undesired microbes, it is not needed for showering. Ever get eye irritation from hot water while showering? Thank the Chlorine. Coincidentally, in the interest of conservation there are showerheads available that produce a very efficient atomization of the water flow at a minimal flow rate. While good for conservation, this is also most efficient for volatilizing Chlorine and other aromatic compounds in the water supply. A good filter (usually an activated charcoal unit, changed regularly) will easily reduce / remove the chemical content. Usage of a moderate flow shower head that does not finely atomize water droplets will also be helpful.

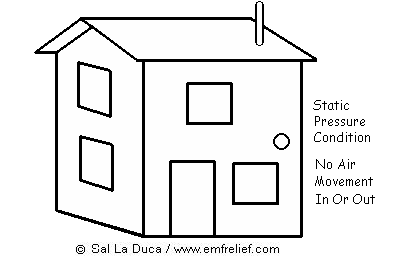

In a tight dwelling, the buildup of pollutants can be dramatically quick. Since a VOC source material may be solid, liquid, or gas (if VOCs are entrained in the fresh air supply), their removal can be a filtration issue (if they are sought to be removed BEFORE they enter the living environment), or it can be a neutralizing / removal issue (if they are sought to be removed AFTER they enter the living space). Access to air / liquid entry paths will most likely determine which method is employed.

In a new home, there are many construction materials that emit copious amounts of VOC out-gas. Exterior walls (essentially being intended as airtight barriers) enclose a few additional sources. While some advocate a home bake-out to substantially reduce VOC emissions (because the present norm is to occupy a house immediately upon completion), the positioning of certain materials beyond moisture barriers, will keep them available as long-term low-level sources of VOCs. When a home bake-out is considered, it is conducted immediately after construction, by raising the internal temperature to a high level (as high as the installed heating system will allow), and then rapidly ventilating the structure. The cycle is repeated several times, over several days, forcing enhanced out-gassing and air volume purging.

There should be NO VOC content in a healthy environment, other than NATURAL emissions from such things as aromatic flowers, wood, etc. A unique source of VOC removal is a ventilation system and hydroculture combination, where a plant\\'s roots are used to scrub the air of VOCs, as humid air is ventilated through them. This a plant air purifier. Plants in general can assist in providing a fresh supply of Oxygen and moisture, as well as remove VOC buildup. Although forced ventilation is very fast in providing air exchange, plants do it without noise, without costly installation, and with pleasing natural settings and aromas. If plants are used, the soil needs to be replaced occasionally, and it should not be kept thoroughly wet, to preclude mold colonization. An inexpensive soil moisture indicator will be quite useful in this respect. Unfortunately, besides plants being slow, they also need to be plentiful to accomplish a sufficient effort at purifying air, essentially forcing you to employ an indoor plant farm to accomplish the goal.

Combustion Products

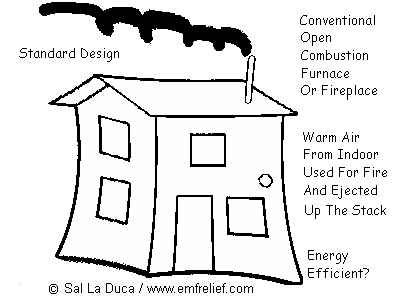

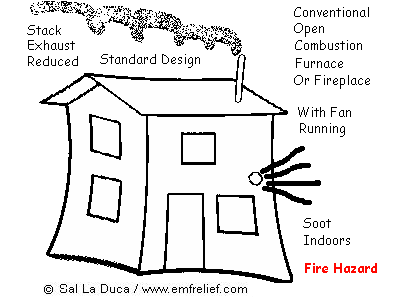

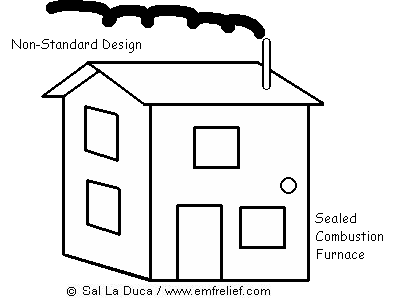

A typical domestic setting is provided with a heat source that feeds a forced air or hydronic system. Most often, the furnace uses indoor air to feed the fire. When the furnace initially fires, before the stack-effect (updraft) is established, there is an initial surge of partially burned combustion products exhuded in all directions. This will produce a localized "smell" of gas or oil within the immediate living space, reminiscent of a leaky exhaust duct. As the updraft is developed, those combustion products are sucked back into the furnace and exhausted outdoors. If there are competing sources of suction elsewhere, such as a clothes dryer, or a bathroom or kitchen fan, those partially burned combustion products can migrate elsewhere throughout the home. During this process, more air needs to be available to feed the fire. A whole-house vacuum (or negative pressure when compared to outdoors) is established, dragging uncontrolled amounts of outdoor air in through window, door, and boundary wall imperfections. Standing near any of these will create a sensation of a cold draft. This describes the operation of an Open Combustion heat source. A conventional fireplace also fits this description.

This is both good and bad.

|

|

|

From an air quality perspective this is very good, as human and animal life is Oxygen dependent, requiring a continuous fresh supply of air. It also can be very bad if there are sources of pollution outdoors, because these would also enter the living environment.

From a comfort standpoint, this uncontrolled air entry is bad because it generally involves very low humidity levels. Personal comfort, as well as reduction in microbial growth potential, is accomplished with humidity levels between 35 - 60%. Wintertime climates can produce humidity levels below 30%. This will produce problems keeping a healthy skin tone, as well as breathing, and eye irritation problems.

The solution does NOT include making doors and windows tighter.

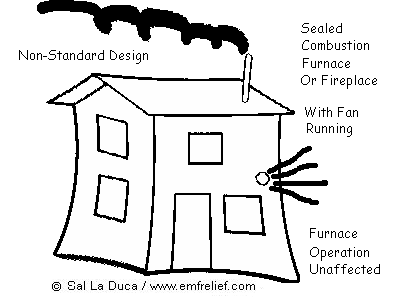

When a furnace and a wood fireplace are both provided, they will compete for the same supply of fresh air. Trying to start a fire in the fireplace while the furnace is ignited might prevent establishing the updraft in the fireplace, bringing all the combustion products indoors.

If the fireplace is not in use, and its exhaust stack is near the furnace\\'s, the exhaust can be recycled back indoors by the negative pressure, unless the fireplace damper is very-tightly fitting (which they seldom are), with consequences.

A partial remedy to the above is to provide an external source of air for furnace (or fireplace) combustion. This concept is then known as Sealed Combustion. Doing so will eliminate the indoor vacuum, and will allow establishing a more controlled moisture level, reducing many related complaints. However, it will present other challenges relating to a fresh supply of air, as removing the indoor vacuum will allow indoor-generated pollutants to build up, eventually reducing the comfort level. I was asked to assess a living space that was regularly causing moisture control issues. The space was remotely heated, so it functioned as if it had a sealed combustion unit. The ventilation for the kitchen and bathroom did not ventilate to outdoors, and simply served as recirculating filters. Simple living necessities such as cooking and bathing then produced copious amounts of moisture, which could not be resolved due to system design, except by opening one or more windows. Obvioucly this was a poor solution of limited use, especially during inclement weather, due to the idiotic thinking of the builder that a living space can be comfortable if it is airtight.

|

|

Ventless heaters should be viewed very, very cautiously. The "ventless" term is a misnomer, because the instructions generally stipulate opening a window about one inch or two. If they use fossil fuel of any type they will need fresh air, and in an airtight space they will compete with the users for that same supply of air. Any buildup of combustion products can be a discomfort or deadly, depending on the level of intrusion. So if leaving a window open in cold weather does not make sense, then a ventless heater also does not make sense.

There should be NO Combustion Products in a healthy environment.

NOTE: mention of any device on this site does not constitute endorsement.